Maximizing Efficiency with Champion Pumps in Industrial Settings

Champion pumps play a crucial role in optimizing industrial processes by maximizing efficiency in various sectors. As a champion pump company, their goal is to provide the best plumbing, waterproofing, and pumping solutions to their customers. With their champion products and services, they aim to be the decision-maker’s go-to choice for any opportunity to enhance the efficiency of their industrial operations. By prioritizing maintenance and incorporating energy efficiency programs, champion pumps contribute to reducing energy costs and emissions, aligning with the objective of decarbonization. By improving pump efficiency and performance, champion pumps help businesses and manufacturing facilities increase productivity and resilience in the face of climate change. Ultimately, maximizing efficiency with champion pumps in industrial settings not only benefits the environment but also boosts competitiveness and offers cost savings for businesses.

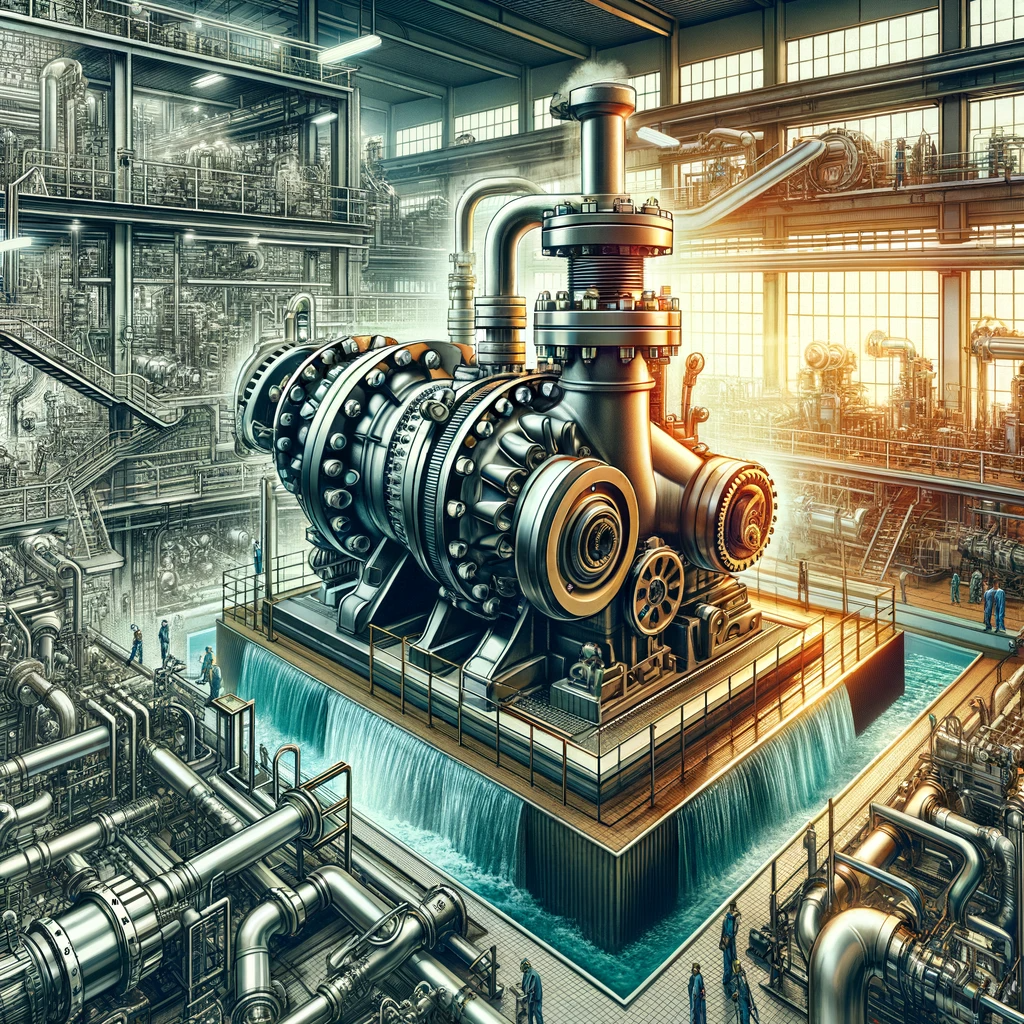

The Role of Champion Pumps in Industrial Processes

Maximizing efficiency with Champion pumps in industrial settings is crucial for businesses looking to save money and reduce their environmental impact. These high-performance pumps play a pivotal role in various industrial processes, from heating and cooling systems to waste management and water treatment. By improving pump efficiency, businesses can maximize productivity, minimize energy waste, and ultimately save on operating costs. Champion pumps are designed to be reliable and cost-effective, ensuring that industries can meet their production targets while minimizing energy consumption. With the right pump improvements, industries can become more energy savers, benefiting not only their bottom line but also the communities and the environment as a whole.

Key Factors Affecting the Efficiency of Champion Pumps

Maximizing efficiency with Champion Pumps in industrial settings is crucial in addressing the climate challenge and conserving valuable resources. Organizations and their partners recognize the importance of efficient pump systems in various industries, including transportation, construction, and utilities. By implementing energy conservation standards and utilizing energy-saving appliances like Champion Pumps, industries can reduce utility bills and create millions of job opportunities in the energy sector. The improved efficiency of pumps not only drives cost savings but also enhances productivity and supports the construction of weatherization assistance programs. State and federal governments, along with American organizations, are taking actions to promote decarbonization efforts and drive the movement towards efficient pump solutions.

Efficiency plays a significant role in the performance of Champion Pumps, particularly in wells and wellbores. The design, size, and type of pump, along with the materials and fluids being transported, all influence pump efficiency. Utilizing the venturi effect, Champion Pumps optimize power fluid flow under various conditions and configurations through jet lift or other pump solutions. Maximizing efficiency with Champion Pumps in well operations can increase overall pump efficiency and maximize productivity in the oil and gas industry. By prioritizing efficient pump systems, industries can contribute to an environment of efficient manufacturing facilities, ensuring that pump performance is improved and energy is used in the most efficient way possible.

Highlighting Multiple Industrial Applications of Champion Pumps

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial, given their wide variety of applications. These pumps are commonly used in the oil and gas industry, where their efficient execution exceeds expectations. Champion offers a range of pump options, including jet pumps, multiplex plunger pumps, and surface pumps, which cater to different industrial requirements. For example, in oil and gas production, jet pumps are often utilized to pump formation fluid to the surface. Petrolift jet pumps, an advanced solution, can efficiently pump both production and wellhead fluid. The nozzle in a jet pump creates pressure effects that allow for the effective pumping of fluids. In addition, jet lift operations can be optimized by controlling the back pressure, diffuser area, and jet pump throat. Champion Pump’s prime pump solutions ensure that the pumps perform at their best, even in challenging environments. With their high-performance levels and versatile designs, Champion Pumps maximize efficiency and productivity in various industrial applications.

Champion Pumps in Heating and Cooling Systems

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial in various applications, including heating and cooling systems. Champion Pumps offer reliable solutions for optimizing gas lift and rod lift systems, allowing for efficient gas lift operations and enhanced production management. The solution sheets provided by Champion Pump are a valuable resource for operators in the field, offering insights and best practices for maximizing the value of their Champion Pump equipment. With features like the web interface and submersible options, Champion Pumps are designed to withstand the challenges of various environments, including those found in Mexico and other oil and gas producing regions. Whether it’s for jet lift case histories or the management of challenging well architectures, Champion Pumps provide the capabilities that technologists and production engineers rely on to ensure efficient operations in the basin.

In the HVAC industry, Champion Pumps play a vital role in achieving peak performance in heating and cooling systems. By offering maintenance contracts and services in the Bay Area of California, Champion Industrial helps customers maintain their HVAC systems and components in optimal condition. Regular coil cleanings and equipment changes are just a few examples of the comprehensive maintenance services provided by Champion Industrial. By maximizing efficiency with Champion Pumps, businesses can minimize maintenance costs, improve production rates, and extend the lifespan of their equipment. With a wide range of material choices, including alloys that resist erosion and corrosion from solids, corrosives, and paraffin buildup, Champion Pumps are designed to handle the toughest conditions. Additionally, their advanced scale and treatment capabilities help prevent formation damage and potential sand or corrosion attacks. Champion Industrial is committed to providing efficient pumps and maintenance solutions that help businesses thrive in an increasingly competitive industry.

Champion Pumps in Waste Management and Water Treatment

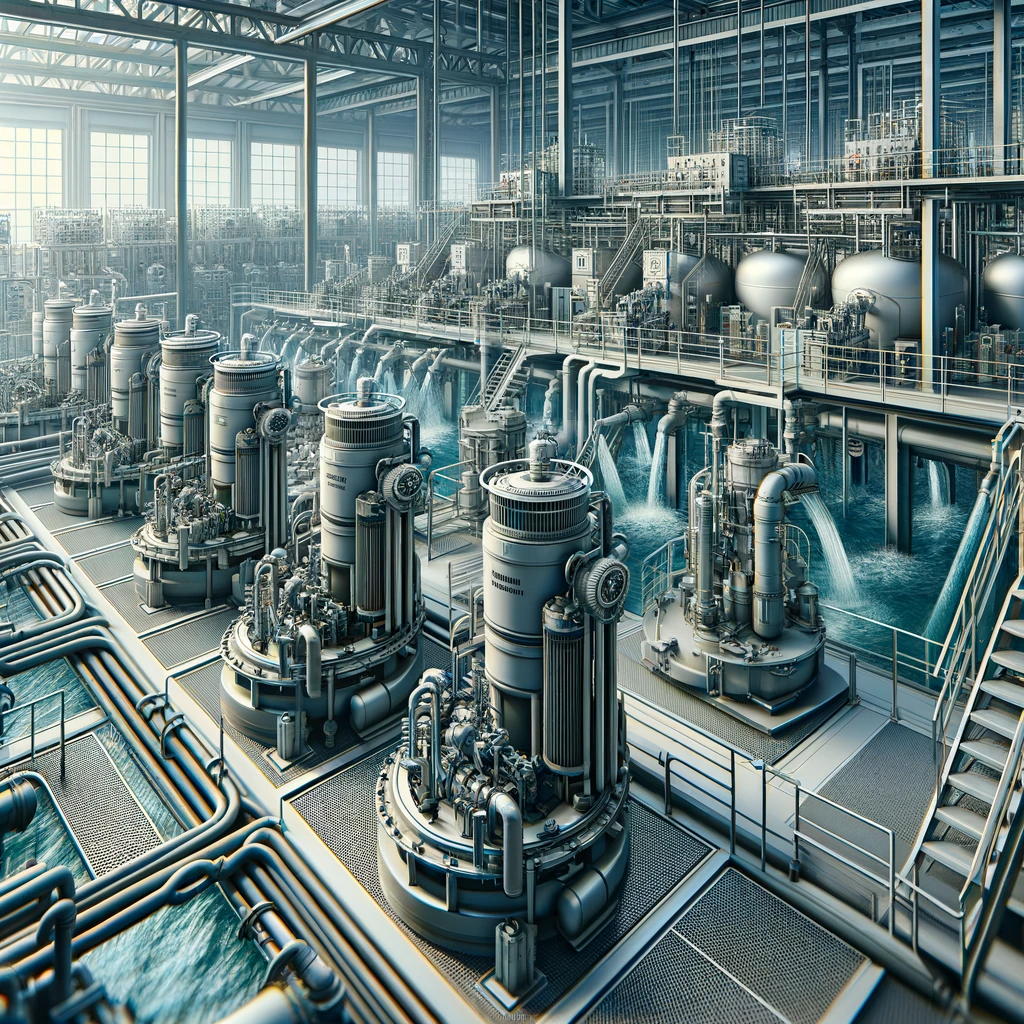

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial for businesses in waste management and water treatment. These industries heavily rely on equipment such as pumps to ensure smooth operations. Regular inspections and maintenance are necessary to address the specific needs of these complex systems. For any emergency repair services, it is important to have technicians on call, ready to provide immediate attention. By having a well-defined maintenance checklist in place, businesses can ensure that their pumps and other devices are working at optimal efficiency. Companies that specialize in pump maintenance and repair, like Champion Pumps, understand the importance of centrifugal pump efficiency and the energy costs associated with it. They offer customized solutions to meet the unique requirements of waste management and water treatment plants, helping businesses maximize efficiency levels and reduce costs in the long run.

When it comes to waste management and water treatment, there is no one-size-fits-all solution. Different industries and properties have varying demands and temperatures to manage. Sewer lines, for example, require special attention to prevent blockages and maintain smooth operations. Champion Pumps provides a variety of pump sizes and types to accommodate different liquid flows and pressures. By incorporating innovative solutions such as sensors and control systems, Champion Pumps helps businesses improve operations and increase pump efficiency. One effective strategy is the use of Variable Frequency Drives (VFDs), which allow users to adjust motor energy consumption according to demand. By optimizing pump impellers and incorporating VFDs into pump control systems, clients can maximize their pump’s performance and efficiency. This strategic approach not only helps in the smooth operation of waste management and water treatment facilities but also contributes to a more sustainable environment by minimizing energy waste.

Champion Pump Performance Enhancement Tips

Maximizing efficiency with Champion pumps in industrial settings is crucial for various industries and applications. Water, liquids, and solvents play a vital role in manufacturing processes, and efficient pumps like Champion can save money by optimizing their performance. One effective method for enhancing pump efficiency is impeller trimming, which involves reducing the impeller diameter by up to 20%. This adjustment allows the pump to operate at its highest efficiency point, resulting in energy savings. The Department of Energy analysis and research center studies have shown that even a small improvement in pump operating conditions, such as adjusting the piping or pressure margin, can lead to significant energy consumption reductions. Another aspect to consider is the pump’s duty point. By operating the pump closer to its best efficiency point (BEP), more than 25% energy savings can be achieved. Regular maintenance, including ring replacement, is also essential to maximize efficiency. C&B Equipment, for example, offers alternative pumping solutions to improve pump performance and efficiency in the water industry. By understanding pump curves and avoiding errors in parallel pump operation, fluctuations in flow rate can be minimized, resulting in efficient and consistent output. Prioritizing pump efficiency is crucial as inefficient pumps are often culprits for increased energy consumption and decreased productivity. For example, in wastewater treatment plants, where pumps operate under heavy load, choosing efficient pumps can be a cost-effective option for maximizing the system’s overall efficiency and extending the life of the equipment. Recognizing signs of pump wear and regularly performing maintenance tasks such as checking rings and impeller condition can help alleviate pump inefficiency and ensure optimal performance. By implementing these tips and techniques, industries can improve their pump efficiency, maximize productivity, and contribute to an environmentally efficient manufacturing facility.

Routine Maintenance for Champion Pumps

Routine maintenance is essential for maximizing efficiency with Champion pumps in industrial settings. Regular wear and tear can cause reduced pump capacity and increased clearance in bearings, leading to cavitation and decreased performance. To prevent these issues, regular upkeep is crucial. This includes impeller and mechanical seal inspection, as well as inspection and replacement of worn parts. Regular services such as lubrication, motor/pump alignment check, and pipe size changes to reduce friction loss should also be undertaken. Proper design phase and pump installation, considering factors like bends, pipe pressure drops, and valve losses, are vital for meeting system requirements. Utilizing optimization software like TM 3.2 or Xspoc can help E&P operators in lift production optimization, with data-driven models and alarm systems for diagnosing and improving system performance. By applying artificial intelligence and plunger lift analytics, anomalies can be identified, operating costs reduced, and results optimized, making Champion pumps the most efficient choice for the industry.

Troubleshooting Common Champion Pump Issues

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial for meeting production optimization needs in various industries. To ensure smooth operations, it is important to address common issues that may arise with these pumps. By utilizing the advanced features of XPSOC, steps can be taken to mitigate risks and improve the overall performance of Champion Pumps. With algorithms provided by Theta Automation, productivity can be maximized, and production systems can operate at their optimal mode. By accessing thetaportal.com, industry professionals can stay up-to-date with the latest trends in lift optimization and gain valuable insights to overcome any pump-related challenges they may encounter.

In order to effectively troubleshoot common Champion Pump issues, it is essential to leverage the capabilities of XPSOC optimization software. This software, supported by a dedicated and knowledgeable team, offers integration with various control modes and equipment databases. By utilizing the well file databases such as WellView, users can diagnose and make recommendations to address pump failures. Furthermore, the software provides solutions for exceptions and supports the identification of uplift opportunities. With the assistance of expert engineers and trend analytics, plunger lift problems can be properly diagnosed, and appropriate measures, including the use of chemicals, can be implemented to improve pump performance. The camera wellsite surveillance feature also allows for real-time user identification, ensuring that XPSOC users have the necessary access and control capabilities. By staying updated with release notes and training videos provided by ChampionX, businesses can maximize their efficiency with Champion Pumps and increase their overall productivity.

Technological Advances Redefining Champion Pump Efficiency

Technological advances have revolutionized the efficiency of Champion pumps in industrial settings. With the introduction of innovative tools and systems, industries have been able to maximize the performance and productivity of their pumps. One such advancement is the incorporation of IoT technology, which allows for real-time monitoring and control of pump operations. By licensing an access to cloud or on-premise optimization modules, industries can analyze case histories and go beyond conventional troubleshooting questions. The introduction of mobile apps and customer support with AI engines has further enhanced the troubleshooting and optimization capabilities of Champion pumps. Additionally, pump performance can be improved by analyzing plunger lift monitor trends, gas lift monitor trends, and rod lift monitor trends, among others. By utilizing these advanced metrics and analyzing historical lift data, industries can identify uplift opportunities and adjust pump setpoints to maximize efficiency. Furthermore, the use of variable speed drives, plunger lift analysis metrics, and injection dosage rates can help optimize pump performance and reduce electricity costs. Overall, these technological advancements have revolutionized the pump industry, enabling industries to achieve higher levels of efficiency and productivity.

Incorporating IoT in Champion Pump Operations

Incorporating IoT technology in Champion pump operations has the potential to maximize efficiency in industrial settings. By connecting equipment such as rod lift equipment to the IoT network, industries can improve rod lift performance by monitoring factors such as injection rates, set points, outflow, and inflow. Real-time data collection and analysis enable companies to optimize performance curves, resulting in higher returns and improved economics. Additionally, IoT integration allows for remote monitoring of valve status, energy efficiency, and pump performance, empowering departments to limit pipework pressure loss and reduce costs. This not only benefits the cooling pump industry but also addresses environmental concerns by conserving energy and reducing waste.

To further maximize efficiency with Champion pumps in industrial settings, engineers should focus on improving pump performance through various ways. This includes utilizing energy-saving techniques such as frequency drives and control systems to optimize pump performance. By understanding the terms flow, motor, clearances, system pipework, safety margin, design process, uncertainties, and oversizing, engineers can ensure that the pump system operates at its highest efficiency levels. Additionally, optimizing fluid and pipework design can reduce cost and energy consumption, meeting the increasing demand for efficient manufacturing facilities. Maximizing efficiency with Champion pumps not only improves pump performance but also contributes to a more sustainable industry by reducing energy costs and minimizing environmental impact.

AI and Machine LearningPowered Champion Pump Systems

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial to meet the duty demands of various applications. AI and Machine Learning-powered systems offer a valuable choice for optimizing pump performance. During the specification stage, it is essential to select the right pump based on duty requirements and system demand. Variable speed drives (VSDs) such as VFDs (Variable Frequency Drives) provide an efficient solution. By adjusting the pump speed to match the system requirements, energy usage can be optimized, resulting in significant cost savings. Furthermore, impeller trimming and casing changes can be made to accommodate specific operating conditions, enhancing pump efficiency. Choosing the right pump for each scenario and employing AI and Machine Learning can greatly improve pump performance and energy usage in industrial settings.

To maximize efficiency and productivity, pump installation and cleaning must be done with care. The pump head, pipework diameter, and valve conditions should be considered during the design stage. Friction losses, pressure drop, and system conditions all play a part in determining the pump’s efficiency point. Stainless steel pumps can be utilized to resist corrosion and rust, prolonging their service life. Pressure switches and wear ring clearance should also be regularly checked and adjusted to ensure optimal pump upkeep. Additionally, pipe diameter and space constraints should be taken into account to minimize leakage and pressure drop losses. By following these best practices and utilizing AI and Machine Learning-powered systems, Champion Pumps can significantly increase efficiency, reduce energy costs, and improve overall pump performance in industrial environments.

Environmental and Economic Implications of Champion Pumps

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial for both environmental and economic reasons. By making deliberate attempts to improve the performance of these pumps, industrial facilities can significantly reduce their energy consumption and costs. One of the key considerations is the proper maintenance and replacement of pump components, such as impellers and seals, which can wear over time and result in energy inefficiencies. Regular inspections and monitoring of pump performance can identify any issues and address them promptly, ensuring that the pumping system operates at its optimal efficiency. Additionally, the design and layout of the piping system should be carefully planned, taking into account factors such as pressure loss, flow rate, and the number of bends and expansions. By minimizing these issues, facilities can maximize the efficiency of their pumps and reduce energy requirements. Furthermore, the materials and weight of the pump itself should be taken into consideration, as lighter and more efficient pumps can lead to energy savings and a longer lifespan. Overall, by prioritizing pump efficiency and implementing energy-saving measures, industrial facilities can not only reduce their environmental impact but also improve their bottom line.

Champion Pumps and Sustainability: An Industrial Perspective

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial for sustainable operations. Efficient pump performance directly contributes to reducing energy usage and optimizing resource consumption in various industrial applications. By addressing common pump repairs such as impeller issues and maintaining pump components, industries can prevent debris accumulation and ensure the pump’s smooth operation. Following a regular maintenance schedule, including inspecting and cleaning pump components, helps maintain the pump’s efficiency and extends its lifespan. For example, in an irrigation system or cooling system, identifying and resolving any pump problems promptly is essential to maintain the desired flow rate, pressure, and performance level. Additionally, the use of Variable Speed Drives (VSD) in pump applications can further enhance efficiency by reducing pressure loss and controlling the pump’s speed based on demand, resulting in significant energy savings. When selecting a pump for a specific application, considering factors such as friction loss, pipe sizes, fluid properties, and construction material is crucial to ensure optimal energy usage and overall pump efficiency.

Conclusion

Maximizing Efficiency with Champion Pumps in Industrial Settings is crucial for businesses and operations in various environments, including the Bay Area of California. Proper maintenance of industrial HVAC systems, which includes heating and cooling solutions, is essential to ensure optimal performance and extend the service lives of the equipment. By implementing regular inspections, expert repairs, and dedicated maintenance plans, businesses can minimize repair costs, improve energy efficiency, and enhance air quality for both staff and customers. Champion Pumps offer reliable solutions for industrial pumping needs, and their expertise and value-added services make them a preferred choice for businesses looking to maximize efficiency and reduce energy costs. By choosing Champion Pumps and partnering with their dedicated team, businesses can achieve their energy efficiency goals while staying within their budget.

FAQ

What is the significance of Champion Pumps in industrial optimization?

Champion Pumps play a crucial role in maximizing efficiency and productivity in industrial settings. They are designed to handle various industrial processes and contribute to overall operational effectiveness.

What is the role of Champion Pumps in industrial processes?

Champion Pumps are used in a wide range of industrial processes such as heating and cooling systems, waste management, water treatment, and more. They help in maintaining consistent flow rates, pressure levels, and ensure smooth operations.

What are the key factors affecting the efficiency of Champion Pumps?

Factors such as pump selection, proper installation, regular maintenance, and system design greatly impact the efficiency of Champion Pumps. It is important to consider these factors to ensure optimal performance.

Can you highlight some industrial applications of Champion Pumps?

Champion Pumps find applications in heating and cooling systems for industrial buildings, waste management processes, water treatment plants, and various other industrial processes that require fluid transfer, circulation, or pressure management.

How are Champion Pumps used in heating and cooling systems?

Champion Pumps are essential components in heating and cooling systems, helping to circulate the fluid medium, maintain temperature control, and ensure efficient heat transfer throughout the system.

What role do Champion Pumps play in waste management and water treatment?

In waste management and water treatment processes, Champion Pumps are responsible for transferring fluids, maintaining pressure, and facilitating filtration or treatment procedures. They are crucial for the efficient operation of these systems.

What are some tips to enhance Champion Pump performance?

Regular maintenance, proper calibration of the pump, ensuring correct operating conditions, and monitoring performance metrics are some tips to enhance the efficiency and performance of Champion Pumps.

What routine maintenance should be performed on Champion Pumps?

Routine maintenance for Champion Pumps includes tasks such as checking for leaks, inspecting and cleaning filters, lubricating moving parts, monitoring fluid levels, and verifying pump alignment.

What are some common issues that can occur with Champion Pumps?

Common issues with Champion Pumps may include clogging or blockages, leaks, reduced flow rates, excessive noise, and motor or impeller malfunctions. Proper troubleshooting techniques can help identify and resolve these issues.

How are technological advances redefining Champion Pump efficiency?

Technological advances such as IoT integration, artificial intelligence, and machine learning are revolutionizing Champion Pump operations. These innovations allow for real-time monitoring, predictive maintenance, and improved overall efficiency.

How can IoT be incorporated in Champion Pump operations?

IoT integration enables remote monitoring, data collection, and analysis of Champion Pump performance. It allows for proactive maintenance, early fault detection, and optimized pump operation based on real-time data.

How are AI and machine learning powering Champion Pump systems?

AI and machine learning algorithms can analyze vast amounts of data collected from Champion Pumps to identify patterns, optimize pump performance, and predict maintenance requirements. This leads to increased efficiency and reduced downtime.

What are the environmental and economic implications of Champion Pumps?

Champion Pumps contribute to environmental sustainability by optimizing energy consumption, reducing waste, and improving overall efficiency. From an economic standpoint, they help minimize operational costs and increase productivity.

What is the industrial perspective on Champion Pumps and sustainability?

Champion Pumps play a crucial role in industrial sustainability efforts by minimizing resource waste, reducing energy consumption, and ensuring efficient operations. They are an integral part of sustainable industrial practices.

Can you provide a conclusion summarizing the importance of Champion Pumps in industrial settings?

Champion Pumps are essential for maximizing efficiency, productivity, and sustainability in industrial settings. With their wide range of applications, proper maintenance, and integration of advanced technologies, Champion Pumps can greatly enhance industrial operations.